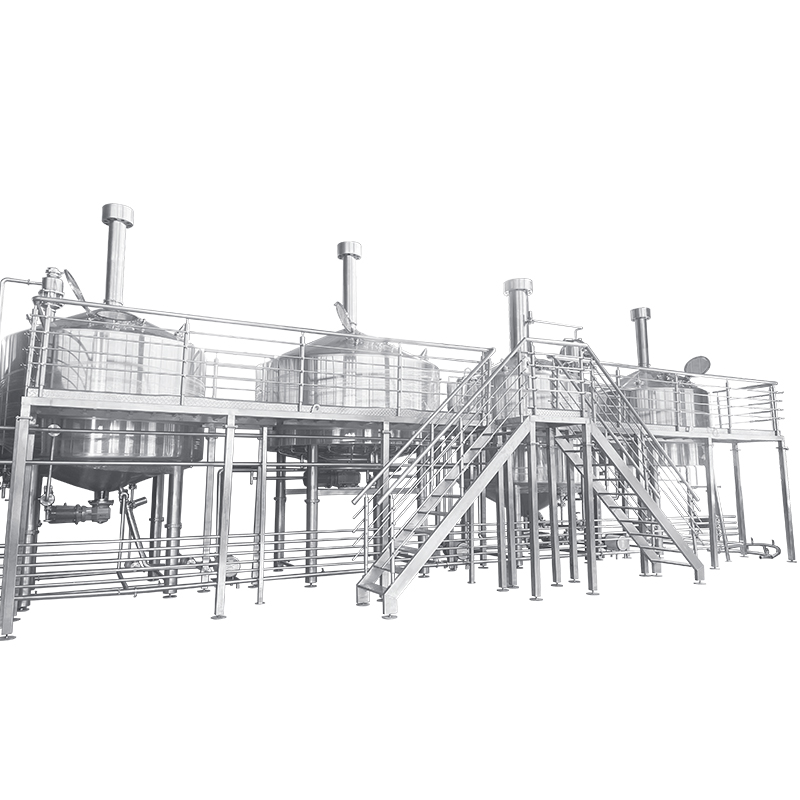

Beer brewing equipment 10BBL 15 BBl 20BBL 30BBL 40BBL steam heating Beer Brewery Equipment for Craft Beer Brewing System

Tonsen is a professional beer equipment manufacturer. We are specialized in the professional design, manufacture, installation and commissioning of beer equipment and supporting facilities. Our products include mashing equipment, fermentation equipment, yeast spread cultivation equipment and refrigeration equipment for small and medium-sized brewery, hotel, pub, etc.

Messages

More

Menu

- Home

- Products

- Brewery Beer Equipment

- Restaurant Beer Equipment

- Home Brewing Equipment

- Brewhouse System For Beer Brew

- Fermenting System For Beer Brew

- Other Machines For Brewery

- Filtration System For Beer Brew

- Cip Clean System For Beer Brew

- Control System For Beer Brew

- Alcohol distillation equipment

- Classification of beer equipment

- Cooling System

- Control System

- Auxiliary Equipment

- Yeast System

- Distillation equipment

- Kombucha Brewing Equipment

- Soda water brewing equipment

- News

- Company news

- Industry news

- Case

- Factory Show

- Beer equipment production process

- Quality first, focus on customers!

- factory equipment

- Contact Us

- About Us

- Certificate

Search