2000l 3000l 4000l 5000l Ale Lager Beer Brewery Equipment

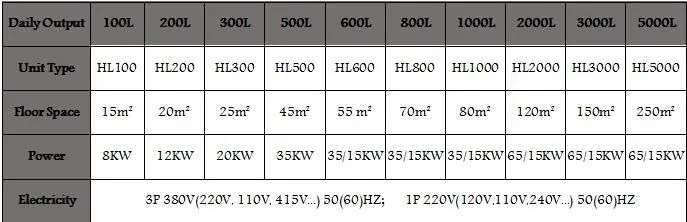

PRODUCT SPECIFICATION:

Our product includes a variety of large, medium and small brewery equipment, hotel, bar home-brewed beer equipment, teaching experiment etc. And could be used to brew various types of wine, beer, barley-bree (whisky) brandy. We supply brewing of main and auxiliary raw material, technical training, secondary equipment and control equipment, of course, can customize according to customer required special specifications design, production, installation of equipment and other products.

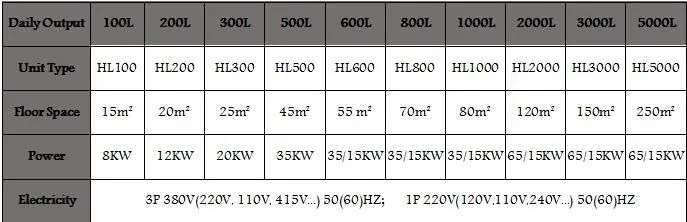

SPECIFICATION LIST

Our brewhouse system separated to 2 vessels, 3 vessels, 4vessels and 5 vessels, capacity from 100L to 20000L, use electric or steam heat. Semi-automatic control and easy to operate.

1)Our Fermentation tanks/tun available from 100L to 20000L (1 gallon to 20 gallon) and average 25% Head Space.

2) All tanks have a Dish top,

3)Cylinder body & 60/70° Cone Bottom.

4)Certified stainless steel(304,316) material for all tanks, with 100% TIG welded joints and seams with sanitary interior polish.

5) Dimple Plate jacket for Glycol cooling & high efficient Polyurethane foam insulated.

6)All tanks use Tri-clamp connections, are designed for up to 14.7 PSI and tested at 30 PSI.

7) We can customize fabricate any tank to meet your brewery’s space and height restrictions.

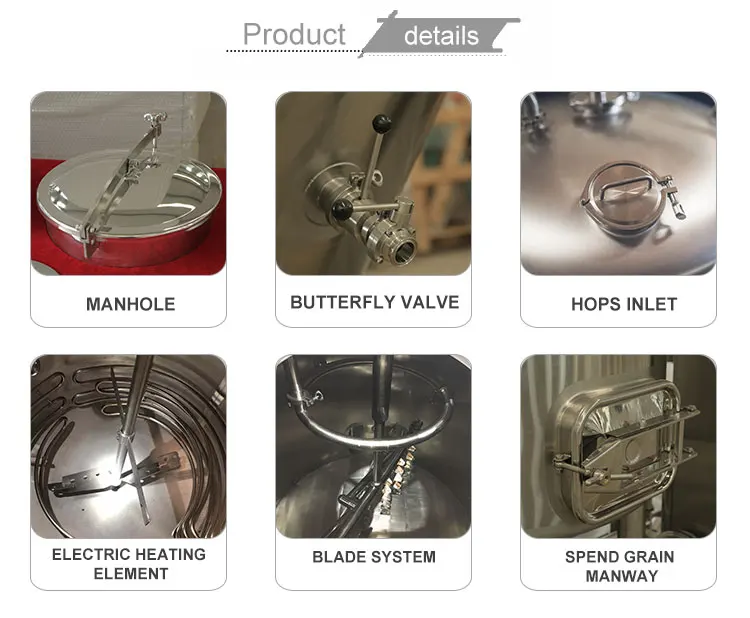

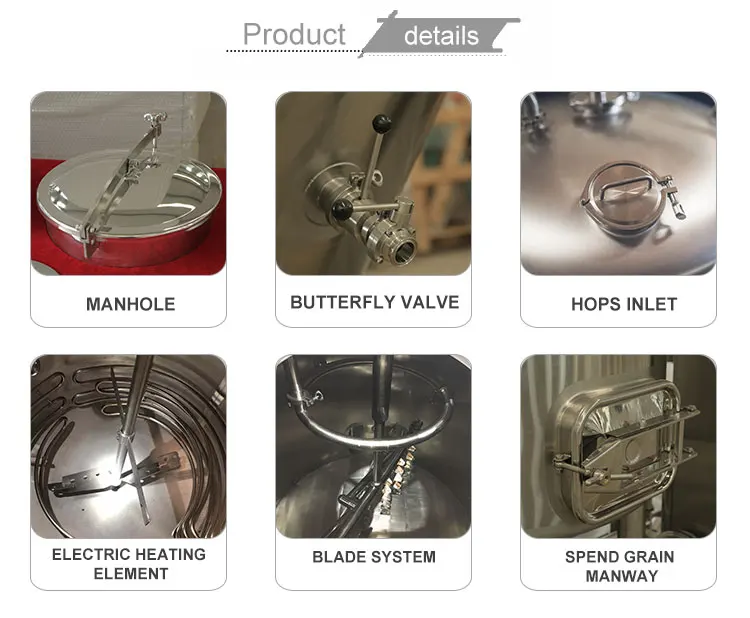

AUXILIARY EQUIPMENT

Mixer(multi-level or continuously variable transmission); sterile respirator(or sterile positive control); inlet and outlet ports; sterile sampling port; observation Master Kong; slagging servant hole; cold water inlet exports; thermometer; CIP cleaning spray; filtering screen device, extraction apparatus, circulatory system.