Some of the Equipment Description:

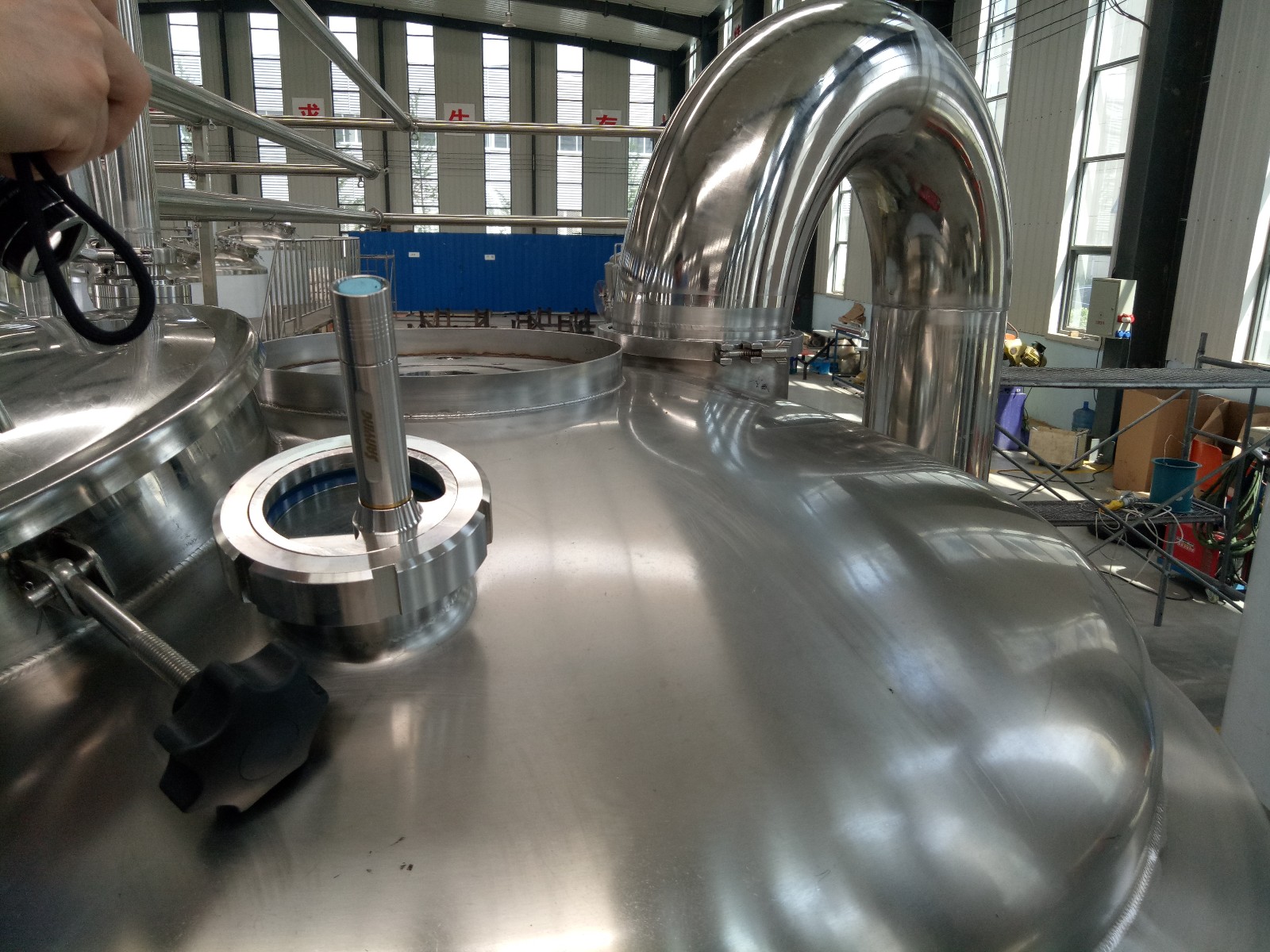

1.The top device of the brewhouse system is our standard dished/dome top.

2.The sieve plate of the lauter tank is equipped with a milling sieve plate, which is flat and smooth, the gap is even, anti-corrosion,high resistance to wear, and the usage life is long.

3.The plow knife of the lauter tank can be customized up and down.

4.The heating method of wort includes three kinds: steam jacket heating, external heating and internal heating.

5. Whirlpool tank is used to separate wort from heat concretion, wort pump into the tank along the tangent direction, form the rotating flow, and leave the heat concration on middle of the tank bottom ,and the clear wort extract from the side outlet.

6.In the process of beer brewing,fermentation requires a lot of yeast,and yeast reproduction requires oxygen,to facilitate the proliferation of yeast and enter the fermentation stage at the same time, venturi tube is the common method for the ventilation of wort.

Detail configurations of Brewhouse System:

-Optional heating way: steam,electric,and direct fire.

-Inner body,inner cone and dome top polished to 0.6μm.The outer handled with surface protection,the welding seam polished to 40mm sandy ribbon strip.Adopt full-TIG welding with pure argon gas shield.

-Stainless steel platform and ladder with horizontal adjustable legs.

-Connected with stainless steel hard piping and configured manifold butterfly valves,tri-clamps,reducing tees and other accessories to joint tanks together.

-Sanitary centrifugal pumps for wort,ice tank,hot water tank,CIP washing to realize medium transfer.

-Mixing: frequency control, more homogeneous mixing, scraping the pot more thoroughly,the lauter tun can be configured with scraper if you like.

-High Efficiency multi-pass plate heat exchanger followed with wort thermograph and oxygenated venturi tube.

-Stainless steel bilingual control panel with digital control that could display the liquor temperature and relevant parameters.

-Compact and space-saving design with flexible brewing configurations to choose from

-If you need to, you can deploy a cold water tank to cool the heat exchanger separately.

Technical Request:

Welding:

Inner body,inner cone and dome top polished to 0.6μm.The outer handled with surface protection,the welding seam polished to 40mm sandy ribbon strip.

Adopt TIG welding with pure argon gas shield.

Test:

After completion,the cylinder body will hold water for test,and the body/cone dimple jacket will withstand pressure test separetely.

The test pressure is assumed to be 0.4MPa.

Note:

1.1Hectolitre(HL)=100Liter; 1Barrel(BBL)=117Liter

2.Voltage/frequency adjust to your local power supply

3.Water supply: water supply, for mashing, cooling, cleaning

4.Material:barley malt,wheat, hops, water,etc.

Packing & Delivery

1)All tanks will be packed with soft protection material and mounted on steel frame

2)All accessories and spare parts will be packed with soft protection material and then put into iron box

3)After loaded into containers, all equipment will be fixed to the containers.