Product Description

Completely Beer Equipment separated to 2 vessels, 3 vessels, 4vessels and 5 vessels, capacity from 1000L to 20000L,applise steam heating way uaually,and electric heating way is optional,with Semi-automatic control and easy to operate.

The 2-vessel equipment usually refer to mash/lauter tank and kettle/whirlpool tank.The 3-vessel could be mash tank,lauter tank,kettle/whirlpool tank,or could be mash/kettle tank,lauter tank,whirlpool tank.The 4-vessel includes mash tank,lauter tank,kettle tank,whirlpool tank.The 5-vessel includes malt mash tank,rice cooker,lauter tank,kettle tank,whirlpool tank.

Mill is used to mill the malt throughly in order to make the dissolution better. In theory, the finer the malt pulverized, the more rapid and complete the dissolving will be.However,in actual production,the malt cannot be crushed too fine, because the malt and starch granules have different properties, and the malt can be crushed only to a certain degree.

Technical Request:

1. Welding

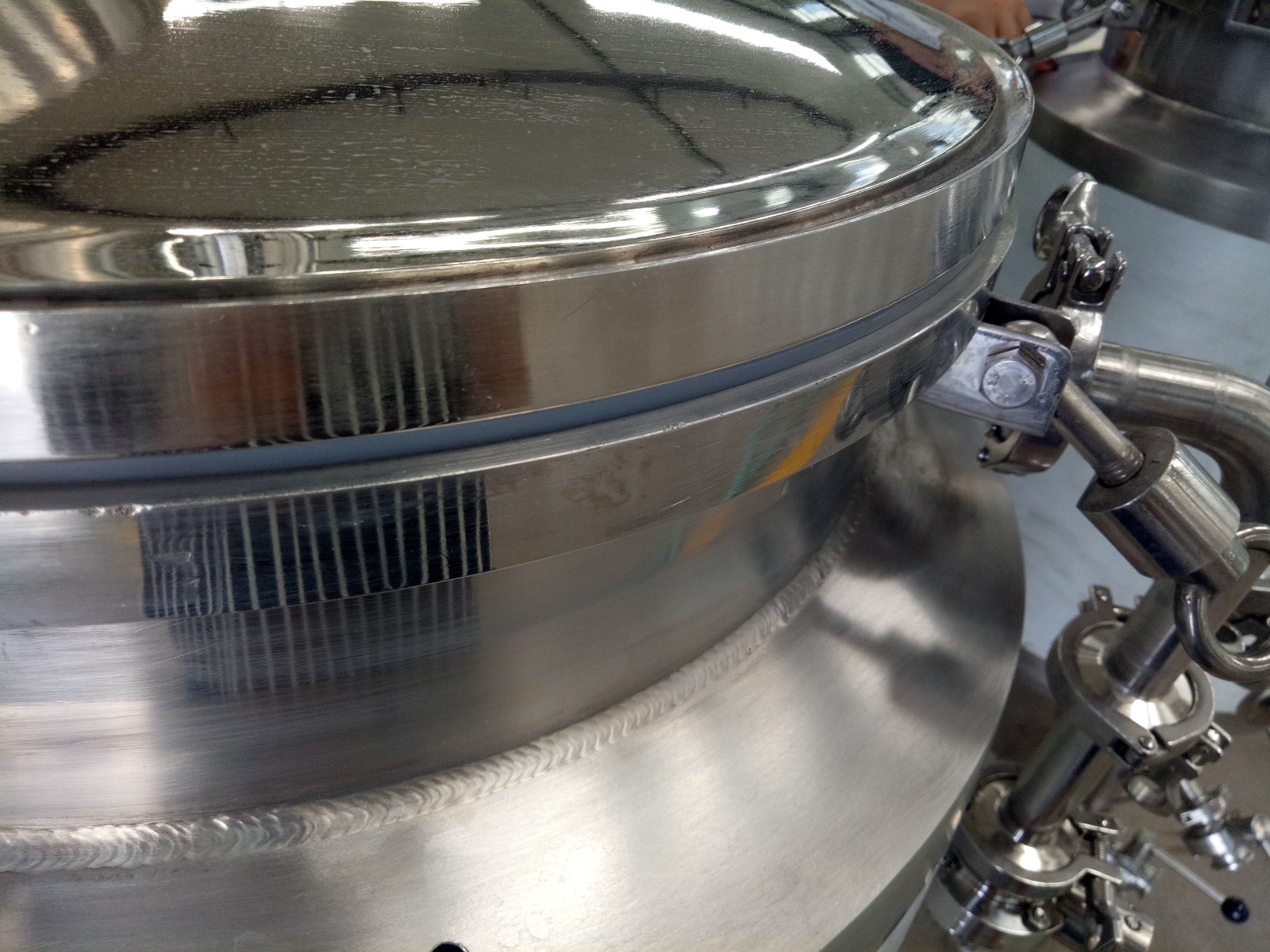

Inner body,inner cone and dome top polished to 0.6μm.The outer handled with surface protection,the welding seam polished to 40mm sandy ribbon strip.

Adopt TIG welding with pure argon gas shield.

2. Test

After completion,the cylinder body will hold water for test,and the body/cone dimple jacket will withstand pressure test separetely.

The test pressure is assumed to be 0.4MPa.

Before-Sales Service

1. Layout Design for new build brewery

Our experienced engineer( more than ten years) will provide the detailed layout according to your brewery, if needed, we will fly to your brewery at our cost.

2. Exist Brewery Expansion

Expansion of the brew house, beer tanks, or other parts, we will design and manufacture as per your exist brewery.

3. Effective business communication

Our sales team are young and rich of experience, we are full of passion, all of us have been in this business line for more than 8 years, and they are graduated from UK, Russia etc.

4. Brewing consultant

Cassman also bult a good relation with Shandong university and other institutes who are expert in beer brewing, we are capable to provide the most advanced brewing technology.

After-Sales Service

1. Guarantee: 3 years

2. Installation: Our engineers team will provide you the perfect installtion and commissioning service. Almost of them have been to 5 countries even more.

3. Our appointed agents are in US, Europe, Russia and other ten countries, they will provide you 24 hours service.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory and welcome to visit us at any time.

Q: How long is your delivery time?

A: Generally single tanks need 20-30 days, for whole plant need 40-50days.

Q: Do you have CE and UL certification?

A: Yes.

Q: What is your terms of payment ?

A: 30% deposit and 70% before delivery.